E6S-Methods Lean Six Sigma Performance Podcast with Aaron Spearin & Jacob Kurian

E6S Industries, LLC

Mission and Vision: The E6S-Methods podcast series is intended for the enthusiast or practitioner of quality, Lean, Six Sigma and other performance improvement tools. Its mission is to provide specific recommendations and different insights and approaches to some of the classic tools, as well as any new tools that may surface. Best practices, tips, and tricks will be shared as well as exploring multiple approaches to reach the same practical end. As this podcast grows in listener-ship, we will entertain listener submissions on specific project issues and use real active projects as a platform for various episodes. To help process managers be their best, E6S Industries strives to be the premier resource for expert training, coaching, consulting, and leadership in lean, six sigma, design thinking, and other continuous improvement methodologies. We are dedicated to finding and sharing the best practices in operations, business processes, project management, innovations and s

- E6S-210 Process Pulse Part 2 - (SPC) 8 Rules

Like / Dislike **We'd Appreciate Your Opinion**

Email me: aaron@e6s-methods.com

Leave a Review! http://bit.ly/E6S-iTunes;

Donations: http://bit.ly/E6S-Donate

Intro: Welcome to the E6S-Methods podcast with Jacob and Aaron, your weekly dose of tips and tricks to achieve excellent performance in your business and career. Join us as we explore deeper into the practical worlds of Lean, Six Sigma, Project Management and Design Thinking. In this episode number 210, we continue our "Process Pulse" series with part 2 - the 8 rules of statistical process control. If you're just tuning in for the first time, find all our back episodes at our podcast table of contents at e6s-methods.com. If you like this episode, be sure to click the "like" link in the show notes. It's easy. Just tap our logo, click and you're done. Tap-click-done! Here we go. http://bit.ly/E6S-210 Leave a Review! http://bit.ly/E6S-iTunes

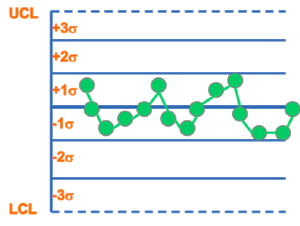

I Western Electric Rules - 8 Rules

a. Identifies low probability events. (Roughly a 3 in 1000 probability event)

i. varies by which Rule

ii. Seems to vary by geography and culture (some want to flag 1 in 100 probability)

iii. Events are neither good, nor bad, just different. The engineer or operator decides if events are favorable or not.

b. Rule 1: one point more than 3 sigma from center line

i. May signify a large abrupt change in the process; requires immediate action

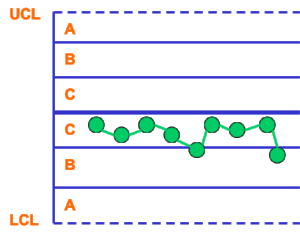

c. Rule 2: nine points in a row on one side of the center line

i. May signify a shift in the process mean or bias in setpoint

d. Rule 3: six points in a row steadily increasing or decreasing

i. May signify a steady trend, drift due to wear, environment, depletion, or increasing contamination

e. Rule 4: fourteen points in a row alternating up and down

i. May signify two sources, bias, or ‘fudged’ data, over adjustment, shift-to-shift / machine-to-machine / person-to-person variation

f. Rule 5: two out of three points (same side) more than 2 sigma from center line

i. May signify an abrupt process shift, high variation without exceeding the three sigma limit.

g. Rule 6: four out of five points (same side) more than 1 sigma from center line

i. May signify a process shift, a step change (operator, procedure, materials)

h. Rule 7: fifteen points in a row within 1 sigma of center line

i. May signify reduced process variation (old or incorrect limits). For Xbar, can signify when variation within subgroup large compared to between subgroups

i. Rule 8: eight points in a row more than 1 sigma from center line

i. May signify a mixture of factors, erratic behavior, over control, two different processes on the same chart

II Typical errors to doing SPC

a. Not doing it

b. Not doing it in real time

i. Doing it a month after the fact for a customer report but not using it to refine your process

c. Leaving it up to the engineer or intern

i. Doing it right means proper training to shop floor and delegating the authority to stop a process if needed

d. Using lack of software or technology as an excuse

i. The most effective way is to be done by hand by the operator making the parts. Shewhart invented it this way.

e. Choosing the wrong type of chart

f. Not updating control limits after a significant process change

III Recap

a. SPC History- invented by Walter A. Shewhart working for Bell Labs in the 1920s

b. Monitors the health (pulse) of the process, and detects unanticipated change. (ekg reading?)

c. Different types of SPC charts - Most Basic I-MR, XbarR, P, U

d. Western Electric Rules - 8 Rules - Identifies low probability events. (neither good, nor bad, just different)

e. Typical errors to doing SPC, 1) Not doing it, 2) Not doing it in real time

Outro: Thanks for listening to episode 210 of the E6S-Methods podcast. Don't forget to click "like" or "dislike" for this episode in the show notes. Tap-click-done! If you have a question, comment or advice, leave a note in the comments section or contact us directly. Feel free to email me "Aaron," aaron@e6s-methods.com, or on our website, we reply to all messages. If you heard something you like, then share us with a friend or leave a review. Didn't like what you heard? Join our LinkedIn Group, and tell us why. Don't forget you can find notes and graphics for all shows and more at www.E6S-Methods.com. "Journey Through Success. If you're not climbing up, you're falling down." Leave a Review! http://bit.ly/E6S-iTunes

Like / Dislike **We'd Appreciate Your Opinion**

21 September 2018, 3:15 pm - fake to fool feedburner21 September 2018, 2:37 pm

- fake to fool feedburner21 September 2018, 2:36 pm

- Fake to fool feedburner21 September 2018, 2:36 pm

- 27 minutes 16 secondsE6S-209 Process Pulse Part 1 - Statistical Process Control (SPC)

Like / Dislike **We'd Appreciate Your Opinion**

Email me: aaron@e6s-methods.com

Leave a Review! http://bit.ly/E6S-iTunes;

Donations: http://bit.ly/E6S-Donate

Intro: Welcome to the E6S-Methods podcast with Jacob and Aaron, your weekly dose of tips and tricks to achieve excellent performance in your business and career. Join us as we explore deeper into the practical worlds of Lean, Six Sigma, Project Management and Design Thinking. In this episode number 209, we introduce various types of statistical process control charts in "Process Pulse - Part 1." If you're just tuning in for the first time, find all our back episodes at our podcast table of contents at e6s-methods.com. If you like this episode, be sure to click the "like" link in the show notes. It's easy. Just tap our logo, click and you're done. Tap-click-done! Here we go. http://bit.ly/E6S-209 Leave a Review! http://bit.ly/E6S-iTunes

*** The Process Pulse - SPC ***

Objection 1: We don't have time to look at and analyze every data point.

Counter 1: SPC will actually save you time, by avoiding major disruptions you could have detected before they became a problem, and by not spending time on common cause signals

Objection 2: We already do SPC, but it really doesn’t help us with anything.

Counter 2: Why? Are you doing it real-time? If you don't use it properly, it's useless. SPC

I Note!: Lots of images in this series. Take a look at the show notes

II SPC – Statistical Process Control

a. History- invented by Walter A. Shewhart working for Bell Labs in the 1920s

b. “Anatomy”

i. line drawing with connected dots

ii. individual plotted points in time order with on the X-axis and key measure on the Yaxis

iii. A center line is drawn at the value of the mean of all measurements

iv. Upper and lower control limits (sometimes called "natural process limits") that indicate “out-of-control” situation

c. Monitors the health (pulse) of the process, and detects unanticipated change. (ekg reading?)

i. Trends

ii. Abnormal changes in variation

iii. Too far from target

iv. See prior episodes

1. E6S-064 - In the eye of the Cash-holder Part 1A- Stable & Capable

2. E6S-065 - In the eye of the Cash-holder Part 1B- Stable & Capable

d. Example: An operator on a ceramics coating process monitors the coating weights applied to each part. The process flags for rule 1 violation for statistically lighter than usual coating weight.

i. Proper action

1. Pause the process (where it makes sense)

2. Inspect the part. Is it still within specification?

3. Investigate the process. Did something change?

4. If part is good and nothing changed, make a note that you investigated the process and continue running as is with no changes

5. If the part is out of spec or something changed in the process. Seek any necessary help to adjust the process. Make a note of changes made. Start the process again.

III Different types of SPC charts

a. Most Basic

i. I-MR – Individual Moving Range (Continuous Data - No subgroups)

ii. XbarR – Mean and Range (Continuous Data - with rational subgroups)

iii. P – Proportions Chart (Discrete/Attribute Data – with rational subgroups)

iv. U – Plots defects per opportunity (DPU) – ((Discrete/Attribute Data – with rational subgroups)

1. When multiple defect opportunities exist on a single unit –

2. output will be an “average count” with some decimal places, if multiple units are being examined

b. Slightly more complex

i. XbarS – Mean and Standard Deviation (Continuous Data - with rational subgroups)

1. When subgroup sample sizes are large

ii. NP – plots individual counts of defective units (as opposed to proportions) – ((Discrete/Attribute Data – with rational subgroups)

iii. C - plots individual counts of defects (as opposed to defective units) – ((Discrete/Attribute Data – with rational subgroups)

iv. Z MR– or “Short Run” – plots points in terms of the “Z” score. (Continuous Data – no subgroups)

1. Analyzed in units of standard deviation

2. Useful for high mix low volume production, where only small samples from each part type are produced.

3. Leverages data from all parts run on the same equipment

v. Laney P and Laney U – adds correction factor for control limits P or U charts to correct for “overdispersion” due to large subgroup sample sizes

c. Somewhat advanced

i. EWMA – Exponential Weighted Moving Average (Continuous data - individual with or without rational subgroups)

1. Plots a combined measurement with some weight given to the previous point and some weight given to the new measurement (no subgroups)

2. Used to detect small shifts from target when process is in control.

ii. CUSUM - Cumulative Sum (Continuous data - individual with or without rational subgroups)

1. Plots a cumulative sum of the deviations of each sample value from the target value.

2. Used to detect small shifts from target when process is in control.

iii. Zone Charts (Minitab only?) – Hybrid of Xbar and CUSUM charts. (Continuous data - individual with or without rational subgroups)

1. Plots a cumulative score, based on "zones" at 1, 2, and 3 standard deviations from the center line

2. Used to simplify interpretation – only one rule (score > 8)

d. Others?…

i. Multivariate

ii. Rare event charts

Outro: Thanks for listening to episode 209 of the E6S-Methods podcast. Stay tuned for episode 210 for "Process Pulse- Part 2," where we discuss the Western Electric Rules. Don't forget to click "like" or "dislike" for this episode in the show notes. Tap-click-done! If you have a question, comment or advice, leave a note in the comments section or contact us directly. Feel free to email me "Aaron," aaron@e6s-methods.com, or on our website, we reply to all messages. If you heard something you like, then share us with a friend or leave a review. Didn't like what you heard? Join our LinkedIn Group, and tell us why. Don't forget you can find notes and graphics for all shows and more at www.E6S-Methods.com. "Journey Through Success. If you're not climbing up, you're falling down." Leave a Review! http://bit.ly/E6S-iTunes

20 August 2018, 1:00 am - 26 minutes 15 secondsE6S-208 Questions from Quora Answered - Part 5

Like / Dislike **We'd Appreciate Your Opinion**

Email me: aaron@e6s-methods.com

Leave a Review! http://bit.ly/E6S-iTunes;

Donations: http://bit.ly/E6S-Donate

Intro: Welcome to the E6S-Methods podcast with Jacob and Aaron, your weekly dose of tips and tricks to achieve excellent performance in your business and career. Join us as we explore deeper into the practical worlds of Lean, Six Sigma, Project Management and Design Thinking. In this episode number 208, we conclude this round of answers to Lean and Six Sigma related questions from Quora. If you're just tuning in for the first time, find all our back episodes at our podcast table of contents at e6s-methods.com. If you like this episode, be sure to click the "like" link in the show notes. It's easy. Just tap our logo, click and you're done. Tap-click-done! Here we go. http://bit.ly/E6S-208 Leave a Review! http://bit.ly/E6S-iTunes

I. Is it compulsory to use statistical tools when doing a Six Sigma Green Belt project (in business)?

II. What is the difference between average and proportion defective?

III. How many level of sigma is NASA?

IV. How do they ensure airplanes operate better than the six sigma threshold?

V. Can Six sigma apply on stock market?

VI. Why does Kaizen Sigma 6 suck so bad for front line trench employees?

VIII. Can you manage a hospital with agile methodology, and what are the best books to read for it?

IX. How many hours a day should a product owner spend in meetings?

X. What are the best books on waterfall startup development methodology?

Outro: Thanks for listening to episode 208 of the E6S-Methods podcast. Stay tuned for episode 209 for our introduction to statistical process control. Don't forget to click "like" or "dislike" for this episode in the show notes. Tap-click-done! If you have a question, comment or advice, leave a note in the comments section or contact us directly. Feel free to email me "Aaron," aaron@e6s-methods.com, or on our website, we reply to all messages. If you heard something you like, then share us with a friend or leave a review. Didn't like what you heard? Join our LinkedIn Group, and tell us why. Don't forget you can find notes and graphics for all shows and more at www.E6S-Methods.com. "Journey Through Success. If you're not climbing up, you're falling down." Leave a Review! http://bit.ly/E6S-iTunes

12 August 2018, 11:47 pm - 21 minutesE6S-207 Questions from Quora Answered - Part 4

Like / Dislike **We'd Appreciate Your Opinion**

Email me: aaron@e6s-methods.com

Leave a Review! http://bit.ly/E6S-iTunes;

Donations: http://bit.ly/E6S-Donate

Intro: Welcome to the E6S-Methods podcast with Jacob and Aaron, your weekly dose of tips and tricks to achieve excellent performance in your business and career. Join us as we explore deeper into the practical worlds of Lean, Six Sigma, Project Management and Design Thinking. In this episode number 207, we continue with more Lean Six Sigma related questions from Quora. If you're just tuning in for the first time, find all our back episodes at our podcast table of contents at e6s-methods.com. If you like this episode, be sure to click the "like" link in the show notes. It's easy. Just tap our logo, click and you're done. Tap-click-done! Here we go. http://bit.ly/E6S-207 Leave a Review! http://bit.ly/E6S-iTunes

III. Are there any good case studies of Lean Six Sigma being applied in a human resources department?

IV. Can we combine Agile with Six Sigma in software development and how?

V. How is RPA connected to Lean Six Sigma?

Outro: Thanks for listening to episode 207 of the E6S-Methods podcast. We continue with more questions from Quora in episode 208. Don't forget to click "like" or "dislike" for this episode in the show notes. Tap-click-done! If you have a question, comment or advice, leave a note in the comments section or contact us directly. Feel free to email me "Aaron," aaron@e6s-methods.com, or on our website, we reply to all messages. If you heard something you like, then share us with a friend or leave a review. Didn't like what you heard? Join our LinkedIn Group, and tell us why. Don't forget you can find notes and graphics for all shows and more at www.E6S-Methods.com. "Journey Through Success. If you're not climbing up, you're falling down." Leave a Review! http://bit.ly/E6S-iTunes

Like / Dislike **We'd Appreciate Your Opinion**

3 August 2018, 1:32 am - 25 minutes 28 secondsE6S-206 Questions from Quora Answered - Part 3

Like / Dislike **We'd Appreciate Your Opinion**

Email me: aaron@e6s-methods.com

Leave a Review! http://bit.ly/E6S-iTunes;

Donations: http://bit.ly/E6S-Donate

Intro: Welcome to the E6S-Methods podcast with Jacob and Aaron, your weekly dose of tips and tricks to achieve excellent performance in your business and career. Join us as we explore deeper into the practical worlds of Lean, Six Sigma, Project Management and Design Thinking. In this episode number 206, Jacob returns and answer some more of the most interesting Lean Six Sigma related questions from Quora. If you're just tuning in for the first time, find all our back episodes at our podcast table of contents at e6s-methods.com. If you like this episode, be sure to click the "like" link in the show notes. It's easy. Just tap our logo, click and you're done. Tap-click-done! Here we go. http://bit.ly/E6S-205 Leave a Review! http://bit.ly/E6S-iTunes

I. Is PMP tougher than a six sigma black belt?

II. What kind of projects would qualify as Six Sigma Green Belt projects(in business)?

III. Why do you work a job that you don’t enjoy?

IV. How did Lean Six Sigma get a 3.4 DPMO?

E6S-011 - DMAIC Define Metrics

V. Is it better to identify waste as TIMWOODI or TIMWOODS?

VI. What is the difference between Six Sigma and ISO?

VII. Can I get the list of companies doing poorly with lean six sigma methodology?

Outro: Thanks for listening to episode 206 of the E6S-Methods podcast. We continue with more questions from Quora in episode 207. Don't forget to click "like" or "dislike" for this episode in the show notes. Tap-click-done! If you have a question, comment or advice, leave a note in the comments section or contact us directly. Feel free to email me "Aaron," aaron@e6s-methods.com, or on our website, we reply to all messages. If you heard something you like, then share us with a friend or leave a review. Didn't like what you heard? Join our LinkedIn Group, and tell us why. Don't forget you can find notes and graphics for all shows and more at www.E6S-Methods.com. "Journey Through Success. If you're not climbing up, you're falling down." Leave a Review! http://bit.ly/E6S-iTunes

24 July 2018, 12:55 am - 27 minutes 30 secondsE6S-205 Beating the Deer Fly - The Price of Victory

Like / Dislike **We'd Appreciate Your Opinion**

Email me: aaron@e6s-methods.com

Leave a Review! http://bit.ly/E6S-iTunes;

Donations: http://bit.ly/E6S-Donate

Intro: Welcome to the E6S-Methods podcast with Jacob and Aaron, your weekly dose of tips and tricks to achieve excellent performance in your business and career. Join us as we explore deeper into the practical worlds of Lean, Six Sigma, Project Management and Design Thinking. In this episode number 205, a short parable, "Beating the Deer Fly - The Price of Victory." If you're just tuning in for the first time, find all our back episodes at our podcast table of contents at e6s-methods.com. If you like this episode, be sure to click the "like" link in the show notes. It's easy. Just tap our logo, click and you're done. Tap-click-done! Here we go. http://bit.ly/E6S-205 Leave a Review! http://bit.ly/E6S-iTunes

Outro: Thanks for listening to episode 205 of the E6S-Methods podcast. Don't forget to click "like" or "dislike" for this episode in the show notes. Tap-click-done! If you have a question, comment or advice, leave a note in the comments section or contact us directly. Feel free to email me "Aaron," aaron@e6s-methods.com, or on our website, we reply to all messages. If you heard something you like, then share us with a friend or leave a review. Didn't like what you heard? Join our LinkedIn Group, and tell us why. Don't forget you can find notes and graphics for all shows and more at www.E6S-Methods.com. "Journey Through Success. If you're not climbing up, you're falling down." Leave a Review! http://bit.ly/E6S-iTunes

Like / Dislike **We'd Appreciate Your Opinion**

*** Beating the Deer Fly - The Price of Victory ***

6 July 2018, 4:07 pm - Fake to fool feedburner27 June 2018, 12:56 am

- Fake to fool feedburner27 June 2018, 12:56 am

- More Episodes? Get the App