The Amp Hour Electronics Podcast

The Amp Hour (Chris Gammell and David L Jones)

Keep Current

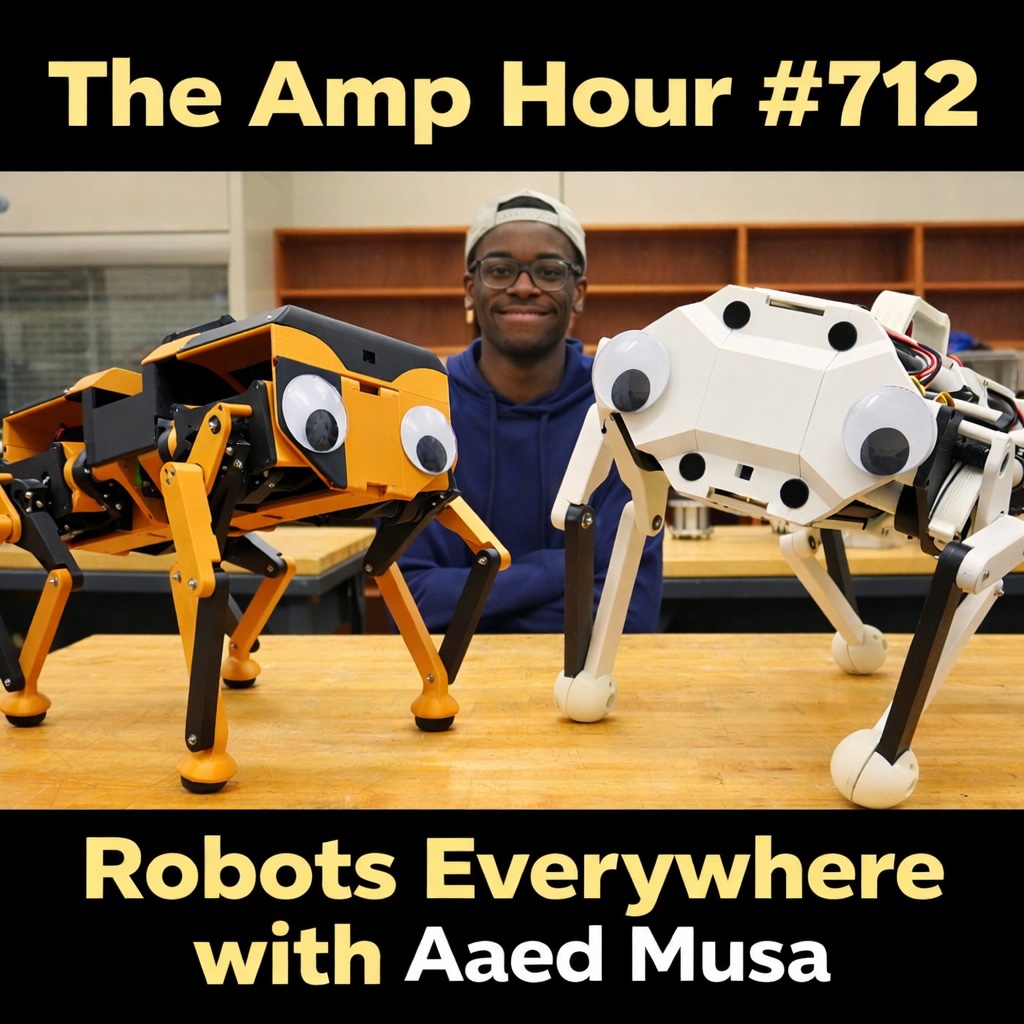

- 58 minutes 37 seconds#712 – Robots Everywhere with Aaed Musa

Welcome Aaed Musa!

- Aaed is a YouTuber who builds a variety of robots and a mechanical engineering student at Purdue. He just completed his undergrad degree and is now working on his Master’s degree. I believe he is the first Amp Hour guest who is still a full time student.

- His channel has a great variety of builds including designing all the way down to gearboxes.

- Aaed says the MIT “mini cheetah” launched many low(er) costs builds of robots, including his own.

- Boston Dynamics (and many others) announced their new ATLAS robotics platform at CES this year.

- FOC motor controller

- Backlash is a measure of how much movement you have between the teeth of gears (and thus how accurate you can be with open loop control)

- Ball bearing balancing robot

- Inverse kinematics

- Past guest of the show James Bruton was a model for the builds that Aaed does

- what does the glue look like

- His recent build uses…rope…to build a robot dog?

- A Capstan drive has virtually zero backlash

- “relatively new rope” DM20

- High precision speed reducer using rope

- the impacts of materials on design processes

- Juicero

- Relationship with classmates and professors as a YouTuber

- Purdue Engineering

- Aaed picked up electronics from youtube

- What’s his take on LLMs?

- Making next CARA open source

- New video recently came out about a spinning top

- bulk of the cost is in the motors and motor controllers

- growing up in the age of youtubers

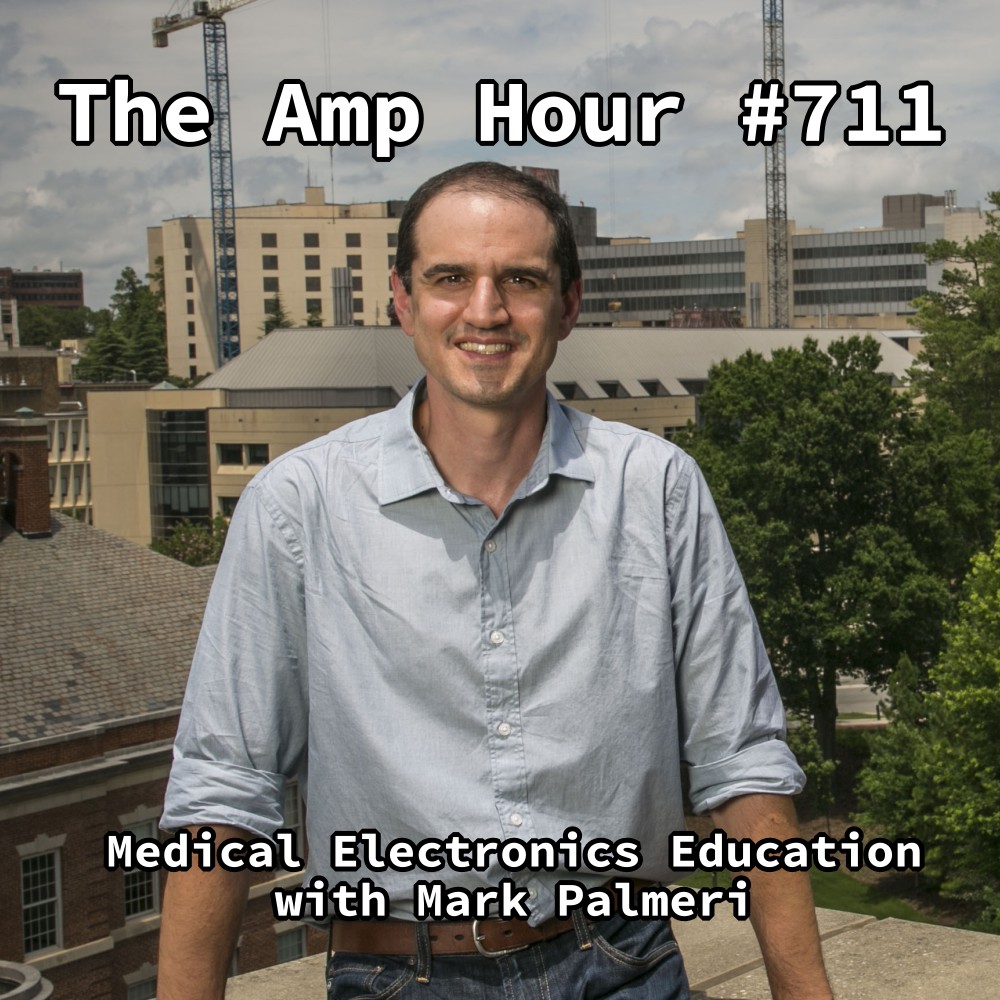

20 January 2026, 4:27 am - 1 hour 29 minutes#711 – Medical Electronics Education with Mark Palmeri

Welcome Dr Mark Palmeri, professor at Duke University!

- Mark has been at Duke since 1996, and has completed undergraduate, graduate, medical, and PhD degrees here (!)

- He has focused on making medical devices and now teaches others to do the same in his Biomedical Engineering (BME) courses

- Verification and Validation (v&v) is a large constraint in getting a regulated medical device to market

- BME design fellows is a program that guides students towards real world use cases and design projects

- The courses that Mark runs reminds Chris of “automatic job offers” that Chris has heard about for classes like those taught by former guest Larry Sears (at CWRU). Also SMPS design courses at UT Dallas and microarchitecture courses like those taught at University of Michigan.

- Teaching the skills of troubleshooting / debug

- Putting together circuits like Legos

- There are difficulties when teaching students with various levels of experience, namely how deep to go on any particular subject and how much background to provide.

- Mark has been flipping a circuit course on its head, instead prompting students with ideas like “how do you capture bio signals electronically and pull them into a microcontroller”

- Tools of the trade for Mark’s courses include

- KiCad

- ngspice (built in to KiCad)

- Jupyter notebooks

- VS code

- Git

- Zephyr

- Talking about power as an intuition builder, as opposed to currents or voltages

- V&V requires that you have a quality management system (QMS)

- IEC60601

- Going through companies that have QMS can be a shorter path for bringing a device to market

- Even face shields needed to go through that process when COVID hit

- Firmware and embedded in BME at graduate level

- Mark and students in BME Design Fellows course have been working on a Tympanometer, targeted at resource constrained industries

- Mark also teaches students how to use Zephyr, as opposed to how most educational programs migrate towards arduino

- A challenge for teaching Zephyr is the devicetreed

- They target Nordic Semiconductor parts, which have great support and educational resources

- Mark experienced a “vertical learning curve” when first migrating designs to Zephyr a few years ago

- Complicating things is that most students haven’t coded in C, if they have done much code at all

- Teaching how to lock to a particular version with Zephyr manifests

- Using CI/CD for automated builds

- Focusing on state machines early on, using Zephyr’s state machine framework (SMF)

- All of Mark’s courses are on github under his username mlp6

- Teaching stack vs heap

- Mark only ever has taken one official progrmming course

- The benefits of experiential learning

- Accreditation is a constant challenge with non-standard courses and testing

- Duke is taking retrospective and prospective looks at the space of education

- Problem sets are moot these days

- Mark gave a great example about teaching a student about Bode Plots

- “Thats a trick problem” is something Mark hears wrt testing (when it’s definitely not)

- “Getting the reps in” is an important concept in educational contexts, and something Chris really resonates with

- Building open ended problems vs closed

- The more open ended a problem, the more time it take to grade / evaluate

- TI-85 / 83 / 92 calculators

- Jupyter notebooks as a way to track progress and have students show their work

- More about the tympanometer project

- They have been working with Duke hospital, a major benefit for Mark and his BME colleagues

- Continuous middle ear infection that causes scarring that causes lifelong loss

- Sound reflection under vacuum is an indicator that more testing is needed

- The key innovation is making it lower cost and allow a layperson to do the screening to hand off a child to get more screening at a pro clinic

- BME Design Fellow students getting to design the various parts of the design

- They have multiple sources of funding: private, nih, etc

- Value engineering in medical space

- Mark points out the philosophical question on whether you can reduce costs by reducing testing … but thinking about whyat that takes to satisfy that need

- Find Mark online

22 December 2025, 7:37 pm - 56 minutes 18 seconds#710 – Tugging on the Nerd Heartstring

- Chris got back from his honeymoon to the Galapagos, see photos on the updated version of his blog.

- Dave encountered a super secret podcast location

- Before leaving on vacation, Chris went to an event mentioned in episode 708 launching a new Tektronix scope.

- The parent company has been Danaher -> Fortive -> Ralliant (now based out of Raleigh)

- Large budget events

- Don Mcmillan is technically funny

- Open Circuit

- The Way Things Work

- Discman teardown

- Neo the home robot

- Humane AI pin ‘tugging on the nerd heartstring’

- Nikola / Trevor Norton

- Auto concept cars

- Rigol MHO 900 videos, already hacked, paid hack

- EEVblog forum

- Unknown chinese fpga

- Stephen Hawes working on a PCB that can be laser cut for super quick turn boards

- Oxide and Friends podcast

- KiCon (US) 2025 Talks

6 December 2025, 8:09 pm - 50 minutes 16 seconds#709 – Nobel Prize Winner Dr Barry Marshall

Dr Barry Marshall won the 2005 Nobel Prize in Physiology or Medicine for discovery of the bacterium Helicobacter pylori and its role in gastritis and peptic ulcer disease.

Dr Barry Marshall won the 2005 Nobel Prize in Physiology or Medicine for discovery of the bacterium Helicobacter pylori and its role in gastritis and peptic ulcer disease.But Barry is also an electronics hobbyist and vintage HP and Tek oscilloscope and vintage computer enthusiast. He visited the EEVBlog lab and sat down with Dave for an impromptu discussion about all sorts of things.

https://www.nobelprize.org/prizes/medicine/2005/marshall/facts/

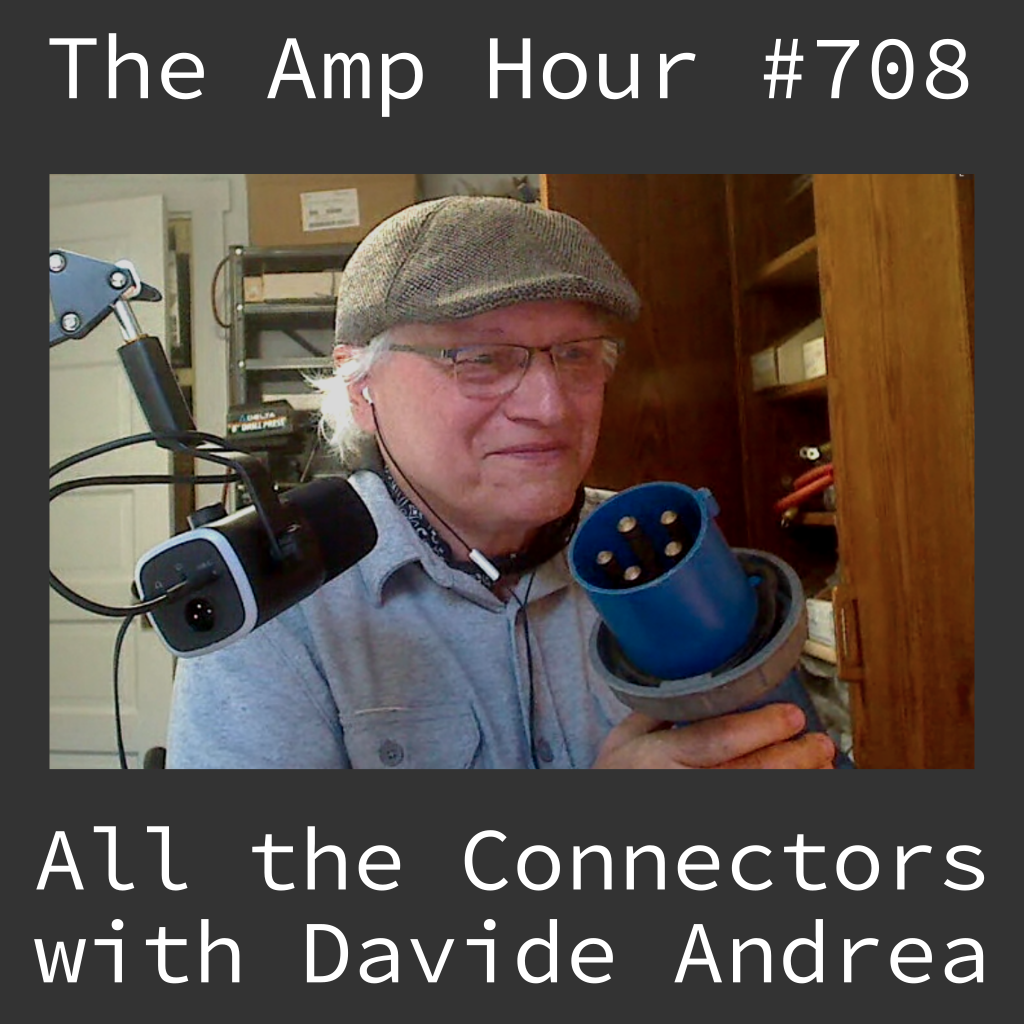

10 November 2025, 3:13 am - 1 hour 5 minutes#708 – All the Connectors with Davide Andrea

Welcome Davide Andrea, author or The Electronic Connector Book! And many thanks to Blues for sponsoring this episode of The Amp Hour! Get 10% off your next order in their online store for a development kit by using the code AMPHOUR.

- Davide is an engineer working on Battery Management Systems at Elithion

- He got into writing and editing books via a postcard sent to him after he gave a talk

- For many years he was an editor at Artech house

- He works on Lithium BMS systems for large setups

- How do young engineers learn about connectors, but for tribal knowledge within larger companies?

- Digikey catalog is a good search for connectors overall

- Industrial cinch by Harting

- Should you design a custom connector (“no”)

- Davide also built and maintains an online tool for finding connectors called Identiconn

- Fretting is when vibration causes a connector to fail

- Davide had to go to Bell Labs docs to look up some specs

- Chris remarked that Identiconn is a McMaster (Carr) style browsing experience

- Vendors divide based on how the fields are set up, because that is actually logical for them selling parts. It’s harder for finding/discovering components though.

- On distributor sites, the connectors are grouped by how they were bought

- Chris asked Davide about things that have gone wrong in his career with connectors

- FFC doesn’t connect back into the socket after the tab is ripped away

- ribbon cable vs ffc, CIC vs FPC

- IDC – insulation displacement connector

- Davide has filled in with generated terms where there are no defined language for a family/type of connector, such as with “bump idc” connectors

- “dual beam?

- Chris and Davide did a joint search for the high density CM4 connector that mounts the Raspberry Pi module to another board

- Gender of connectors (note: there is a great discussion about the historical nature of using gender for connectors in the book)

- Pin vs plastic gender

- Shrouded vs enshrouded

- gaziatea (sic) – poem from the 1800

- USB type A connector

- Self mating

- APC7 – self mting connector

- Anderson connectors

- TNC BNC search

- PFFE for the dielectric on a BNC/TNC

- Magnetic connectors with pogo pins

- Example connector from Hyte

- Crimps were designed in the 50s

- The source of having so many power connectors is … imperialism? tahiti / fiji / nz all have different connectors

- Why antennas are male/female is…money? And regulatory silliness via the FCC

- Davide has also written about and is working on lithium ion batteries

- A sodium ion battery book (self published, unlike the LiIon books) should be out next year

- The Connector Book is self published. Your purchase directly supports Davide’s work…and you get the web tools for free!

- “peak lithium”

- What is required when refining sodium for batteries?

- The voltage range and charging needs are different for Sodium Ion. For instance, the range goes from 4V to 2V

- Find Davide on his various websites, on LinkedIn, on StackExchange, and on reddit

3 November 2025, 3:49 am - 50 minutes 41 seconds#707 – Welding with an HDMI Cable

Thanks to our sponsor Blues this week! Visit the Blues store and use the code AMPHOUR to get 10% off your first order of a kit.

- Capacitors go pop on Dave’s audio setup, the Presonus monitors

- Ground loops causing HDMI cable sparking

- Chris was watching Jetman videos and got an ‘Is that real?’ from the kid. We find ourselves asking the same with all the AI generated video these days.

- Fight between mehdi/electroboom and walter lewin about KVL

- Arduino bought by Qualcomm! They also released the Arduino Uno Q, a single board computer running Debian that also has a beefy microcontroller running Zephyr

- Daves post on X about the purchase

- Arduino switched to Zephyr

- A new enabler of this complex mix of embedded, linux, AI, and ML is a software offering from Arduino called App lab

- Spacey

- Hardware meetup – ACES

- Veritasium is PE owned now

- Chris will be going to a Tektronix event for new gear and past guest Alan Wolke (W2AEW) is giving a class

- Chris has been rebooting his website to follow the ideas of the Small Web

- Follow #electronicscreators on YouTube to not be subject to algorithmic steering

- Chris has been getting into gridfinity after discussing it a few shows ago.

- Altium changed their pricing again…but it might be lower? Hard to tell

- Check out the features coming to KiCad in v10

- YOLO = “You Only Look Once”, Chris learned about it from OpenMV

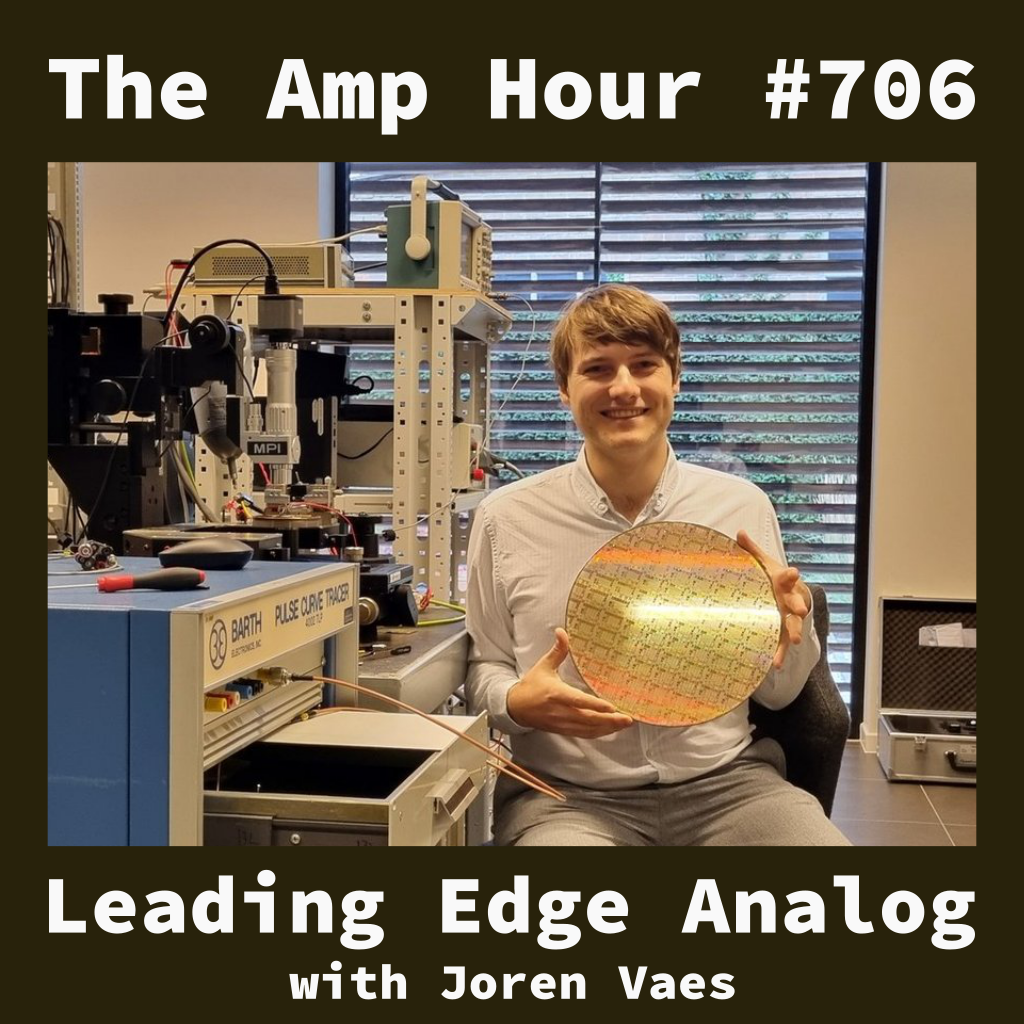

28 October 2025, 1:13 am - 1 hour 4 minutes#706 – Leading Edge Analog with Joren Vaes

Welcome Joren Vaes, design engineer at SOFICS

- Simulation is critical when designing analog devices based on a PDK from the fab

- Parasitics are significant, especially with new nodes having upwards of 16 metal layers

- Chris complained about a class where the professor made them draw planar structures with graph paper with colored pencils

- Large fabs on leading edge nodes have 1800 page textbook of rules

- Because the constraints get tighter, that book gets longer for each node

- 2 nm mass production on finfet currently with TSMC

- 22 was the last classic cmos

- Finfet, looks like a devil

- ‘gate all around’ / nanosheet

- CFET (complementary field effect transistor) is next

- Joren really gets Maxwells Equations…as you have to at super high speeds

- SOFICS are making phy’s / IP blocks

- Amplifiers that are DC to 50 GHz

- Making a datasheet for the resulting IP block

- Joren got his PhD working on millimeter wave applications

- It’s all just physics

- Using coils to impedance match between layers

- Reflecting off of different materials at angles is Snells law (not lorentz equation) and that extends to different materials at different wavelengths

- Cables are very lossy at 100 GHz…dBs per cm

- Parasitics impact every part of the design process

- Wireline community – name for the high speed interfaces, including research in the space

- Most transistor threshhold voltages that Joren works with are … 750 mV!

- Voltage dependent drc rules

- Electromigration – holes in wires from electrons

- ESD is a big part of the business, and a large source of parasitics

- New product development for IP blocks

- Working with customers and Foundry at the 2 nm node

- Design companies need to be paying 100s of thousands to software providers

- After, it goes to spice and schedmatic

- Joren decides whether to jump in on layout

- LVS – layout vs schematic

- Parasitic extraction (spice netlist)

- PDKs define how you can do the layout stage

- Lower cost tools exist but more expensive tools have tooling that tells you when you’re violating DRC

- 3 main vendors

- Cadence

- Synopsis

- Siemens (Calibre)

- Foundries soemtimes only support one tool

- Doing test wafers allows testing of structures. They often get MPW at a discount from the fab (since they’re often testing new processes as well)

- How do they test with packaging options?

- ‘low speed’ can be die bonded or pcb mounted

- high speed does on wafer probing (with veeeery expensive probes)

- Check out Sofics.com for more info on the company. They also have a blog with a great name.

- Follow or connect with Joren on LinkedIn

18 October 2025, 7:20 pm - 46 minutes 7 seconds#705 – Psst…Hey buddy, wanna buy an Octopus?

- Contextual Electronics is “still a thing”.

- Sydney hosted the International Astronautical Congress (IAC). The IAC is the “big space event of the year,” held annually in a different city.

- Chris noted that US space funding seems low, leading some friends to move from NASA to private industry.

- Dave recorded two walkaround videos: a 30-minute bird’s eye view using a GoPro on a pole and a physical hour-long walkaround.

- Large companies had private stands, while smaller, two-man companies had sub-booths within their country’s larger rented stand (e.g., South Africa, Germany, Poland).

- Niche companies included those selling “space connectors,” described as regular connectors sold at potentially 10 times the price to space customers.

- Australia had a large presence, with stands for the country and individual states (Victoria, New South Wales, Tasmania) hosting local niche space gear firms.

- Dave toured a new, completely mobile Mission Control facility built into a semi-trailer van. This unit is designed as a generic platform with screens, server racks, and redundant power, allowing any space company to install their own servers and operate anywhere in Australia.

- An Australian company specialized in “Space lube” (lubricants for satellites and actuators), necessary because water-based lubricants would boil off or freeze up and cause gear to seize.

- Chris has a new “quasi obsession” with the old technology of DIN rail. He is using 3D printers to mount development boards onto DIN rail to organize his desk.

- DIN rail is common in Australia and Europe for electrical switchboards and automation equipment (PLCs, power supplies).

- Dave sent a photo of “Fish Pointer’s” organized desk, which Chris identified as using “Gridfinity,” an ad hoc, modular standard popular in the 3D printing community, often associated with Zack Friedman of Voidstar Labs.

- Dave runs a Creality K1 3D printer that is networked, allowing him to control and print remotely.

- Chris purchased a filament dryer for only $42 to combat the issue of filament going brittle due to moisture.

- Dave recounted his attempt to sort 330 tins of salvaged parts (feet, spacers, grommets) from vintage test gear.

- The space industry is currently “so hot” due to private funding, unlike the “dead” industry 10 to 15 years ago.

- It is now easy to book a payload slot on a launch vehicle like SpaceX. Dave said that Firefly was actually “begging” people to put payloads on its Moonlander to help fund the mission, though that’s source unknown. It was supported by CPLS as part of NASA.

- The Commodore Corporation recently changed hands, and a consortium of enthusiasts released a new Commodore 64 Ultimate, featuring a transparent keyboard PCB signed by original designers, including Jerry Ellsworth. The appeal is nostalgia, as modern chips far outperform the 6510 CPU it uses.

- Chris bought a split, ergonomic Corne V4 keyboard (RP2040 chip) from AliExpress for $68. The key feature is working with Vial, a pleasant web serial-based app for reconfiguring key mappings. Dave stated he hates split keyboards and rechargeable keyboards that only last a week.

- Dave is installing 75 kWh of beefy outdoor battery packs (800-900 kg total) received “free” due to a government subsidy.

- He poured a new, completely reinforced concrete slab rated for over 1,500 kg to support the batteries on a flat surface, using pre-welded mesh instead of tying rebar.

- The new system includes an 8 kW inverter. Dave intends to install a changeover switch to run the house off the batteries if the power grid fails. Dave noted he mainly wants the “warm fuzzy” feeling of running his entire house on solar and batteries.

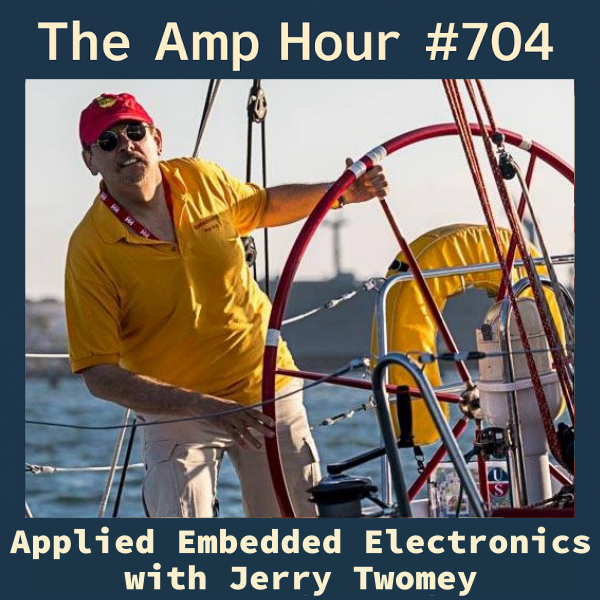

9 October 2025, 2:28 am - 50 minutes 46 seconds#704 – Applied Embedded Electronics with Jerry Twomey

Welcome Jerry Twomey (Effective Electrons) author of the book, Applied Embedded Electronics: Design Essentials for Robust Systems. Chris first heard Jerry on Embedded.fm last year.

- Jerry’s Background and Book Motivation: Jerry shares his quick history, moving from the Boston area to San Jose (Silicon Valley) and eventually to San Diego, where he has worked across diverse sectors including consumer electronics, aerospace, defense projects, DARPA research, and medical electronics. His book focuses on how to develop robust systems, providing guidance that is timeless rather than applications manuals that quickly become outdated.

- The Analog Problem: Although modern systems may be digital end-to-end, Jerry emphasizes that the predominant causes of failure and design difficulties are often analog in nature. Academic study often teaches ideal signals but neglects real-world issues like inductance, noise, and cross-coupling.

- Consulting Experience & Troubleshooting: Jerry discusses being called in to fix systems that failed strenuous regulatory testing for medical devices, where reliability is first and foremost (similar to an aerospace way of thinking). Failures often stemmed from basic issues like a lack of ESD protection, absence of error correction in data streams, insufficient detection of errors, and common mode noise rejection problems.

- High-Speed Data and Signal Integrity: At high data rates, communication becomes a “communications channel problem,” not truly a digital one. When bits are underneath a tenth of a nanosecond, the communication turns into multiple standing wave transitions. The two primary limits on performance are rise and fall times and distance traveled.

- Real-World Applications: Jerry has worked extensively on medical devices, including early-generation Dexcom glucose monitoring systems (two on-body monitors and a hospital insulin pump/monitor), and a wearable EEG monitor. He also worked on a system that required packing five video cameras into an endoscope distal head, measuring 11 mm in diameter and 13 mm long.

- Architecting Systems and Identifying Bottlenecks: When starting a new project, Jerry suggests defining needs and interfaces and looking at the system as a black box. Engineering time should focus on the bottleneck—the hardest part of the system. For medical implantables, this might be minimizing power consumption down to virtually nothing, which could take up 90% of the effort.

- Power System Design: Jerry advises purchasing commercial AC-to-DC converters due to competitive pricing. He notes that switching supplies (buck converters) commonly introduce noise that can lead to EMI failures or corrupt sensitive analog front ends. A classic case of “digital thinking in an analog scenario” is when a sensitive analog front end is powered by a noisy switching converter.

- Working with Embedded Teams: Jerry prefers guiding embedded teams toward “self-discovery,” using bench time and empirical measurement (such as comparing grounds on a scope) to demonstrate non-ideal connections and grounding issues. He advises against the “seagull manager” approach.

- Grounding Best Practices: For integrated circuits (chips), designs must be fully differential because securing a good hard ground reference is impossible. On singular circuit boards, a common uncut ground plane (dedicated ground plane, often multiple layers stitched together with vias) is the recommended approach. Cutting the ground plane is discouraged as it can create a slot antenna, increasing the signal radiating from the board by about 7 dB. Jerry has published rules on grounding.

- Engineering Intuition vs. LLMs: Jerry notes that intuition is gathered through painful learning experiences and guidance from experienced designers. He expresses concern over the reliance on LLMs (Language Learning Models), which, while improving, can confidently provide incorrect answers, especially regarding complex topics like signal grounding.

- Limits to Moore’s Law: CMOS scaling is approaching physical limits, likely unable to go below 10 or 11 nanometers. Modern performance gains are achieved through more parallel processing, not significantly faster clock rates, which have plateaued around 5 GHz due to parasitics and timing limitations. Jerry’s article discusses this topic.

- RISC Architectures: The industry benefits from migrating to RISC (Reduced Instruction Set Computing) architectures (like ARM) because they eliminate useless architecture and transistors associated with complex instruction sets (like x86).

Find Jerry on Effective Electrons and on LinkedIn

3 October 2025, 1:19 am - 58 minutes 13 seconds#703 – Building wafer.space with Tim Ansell

Welcome back Tim Ansell!

- Tim’s past appearances and previous work

- Discussing Tomu on 375

- Discussing Fomu on 456.3

- Discussing the open source PDK on 501

- Tim’s previous work at Google involved releasing a manufacturable open-source PDK (Process Development Kit), which contains the fundamental information needed to create integrated circuits.

- Key open-source tools discussed include OpenROAD (a backend compiler for IC design) and Open Lane (an end-to-end suite turning chip descriptions (RTL) into manufacturing data (GDS)). Andreas had been on the show talking about his work on OpenROAD. Not discussed on the show but after Efabless went away, Open Lane has been replaced with LibreLane.

- Efabless, a VC-backed startup, shut down in early 2025 due to investor disagreements. Efabless previously provided pooled manufacturing access (similar to OSH Park for PCBs) using the SKY130 process from Skywater in Minnesota.

- A Skywater run costs $200k–$300k, which Efabless divided by 40 to reach roughly a $10k price point per slot.

- Tiny Tapeout

- Matt Venn’s Tiny Tapeout program further subdivides the manufacturing costs, making it the cheapest way to create custom silicon, typically costing around $300 per design.

- Tiny Tapeout lowers the barrier to entry, allowing people to “just try it and see if you like it,” similar to writing a “hello world” program.

- The program has already processed almost 3,000 projects, demonstrating high community demand when costs are low.

- Despite limitations, advanced projects are possible: a developer taped out a Linux capable SOC using open-source tools and the Tiny Tapeout space.

- Introducing Wafer Space

- Tim started Wafer Space, based in Singapore, to provide community access to open-source manufacturing after Efabless ceased operations.

- Wafer Space focuses on the GF180MCU PDK (Global Foundries 180 nm process), which is a much cheaper technology manufactured in Singapore.

- The core offering is a low-volume production run: $7,000 USD gets you 1,000 chips back. This volume is enough for prototyping and shipping a small product (e.g., 500 units).

- The design envelope area is 3.8 x 5 mm (20 mm squared) using the 180 nm process.

- Interested parties should sign up via the Crowd Supply page. The deadline for purchase is the November 28th and submissions are due by December 3rd, with delivery by March 15th.

- Manufacturing & Packaging

- By default, customers receive bare silicon die

- Tim is working with PCB manufacturers (like JLC PCB, PCB Way, Seed Studio) to offer Chip on Board (COB) wire bonding assembly onto custom PCBs (think black epoxy blob on a PCB)

- COB packaging is significantly cheaper (sub-$2) than standard packaging houses (which often charge around $7 per chip).

- This approach also provides faster iteration speed, as PCB manufacturers offer quick turnaround times (sometimes 3 days) compared to typical packaging houses (3 months)

- Getting Started & Resources

- If you are new to chip design, starting with Tiny Tapeout’s click and drag tools is highly recommended. Matt Venn previously talked/sang about Siliwiz

- More advanced tools include Verilog and VHDL (coding style) or KLayout and Magic (drawing shapes, similar to PCB design).

- To follow the project or seek help, join the Wafer Space Discord

- New services offering open-source silicon manufacturing include IHP (Europe/130 nm) and Chip Foundry (US/Skywater), increasing ecosystem resiliency.

- Website: Wafer.space

- Sign up on the CrowdSupply campaign

25 September 2025, 1:15 am - Tim’s past appearances and previous work

- 1 hour 6 minutes#702 – Test Point Accupuncture

- Dave bought a lemon laptop

- Chris officially has solar that is installed, working, and is effectively an appliance at this point…

- Duke Energy and North Carolina nuclear mix

- The impact of batteries on the grid

- The Duck Curve is something Chris and Ari discussed on ep650

- Open circuit voltage on panels

- Dave did a repair on a tennis ball machine

- Chris designed a board with test points too small

- Accupuncture jbc

- High cost vs low cost rework tweezers

- Nanofix YouTube Channel

- Tested

- Ugly multimeter review

15 September 2025, 2:34 am - More Episodes? Get the App